Rallys of regularity are characterized by the fact that the participants must make a determined journey in a time as close as possible to the one established by the organizers. The lower the difference, the better the score is awarded to the competitor, and the one who gets the best score by completing the stages is declared the winner of the race. That is why a lot of expertise and good precision devices are needed that work properly.

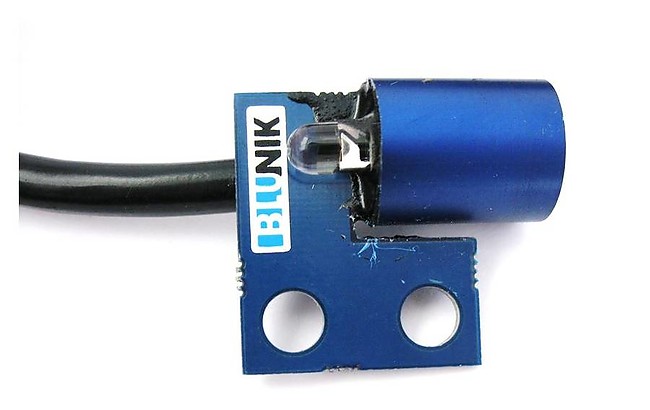

One of the essential elements are sensors, whether magnetic or inductive, but in any case, their correct placement will depend on the good operation and accuracy of the device. Let's talk in this article about magnetic sensors.

On many occasions, we received inquiries because an installed sensor that was working, suddenly, has stopped working. Once the necessary investigations and questions were made, we see that on 99% of the time both the magnetic sensor and our Blunik II work perfectly. So that, what has failed? To understand a bit more the problem briefly let’s explain how a magnetic sensor works.

One element that comprises a sensor is to have it detecting the direction parallel to the magnetic field at a certain distance. Its omnipolar characteristics allow the activation of the sensor by a north or south pole and allows to measure the magnetic induction in regions where there is presence of magnetic field. Therefore, when we provide a sensor, we do it with an element that has a magnetic field: a magnet.

The magnet is neodymium NdFeB in the form of a small disk and has 3360 Gauss with a clamping force of 0.5 kg. However, depending on certain factors, the magnet may lose its magnetic properties and, therefore, neither allow the activation of the sensor nor the correct operation of the Blunik II device. That is why the placement of this magnet is the key for everything to work properly..

Most N-type neodymium magnets lose part of their magnetization at 80°C permanently. Conversely, intense cooling (eg liquid nitrogen) does not cause damage to neodymium magnets.

If a magnet exceeds its "maximum use temperature", it will lose some of its magnetization. Thus, it adheres with less force, eg. to an iron plate, even after it has been re-cooled. From a certain temperature, called "Curie temperature," there will not be any magnetic remanence.

A brake disc can reach between 300° C to 500° C in its braking process, so that a magnet attached to the disc would quickly lose its magnetization. So that, it does not seem a clever idea to place the magnets on the disc brakes or anywhere else that reaches high temperatures, but to make a stand where the magnet is ventilated always away from elevated temperatures to guarantee its magnetic properties allowing the device Blunik II correctly read the activation of the magnetic sensor.